Industry News

BLDC Motor Working Principle

Brushless DC motors consist of permanent magnet rotors, multipole winding stators, and position sensors.

BLDC Motor Working Principle

Brushless DC motors use semiconductor switching devices to achieve electronic commutation, that is, electronic switching devices replace traditional contact commutators and brushes. It has the advantages of high reliability, no commutation sparks, low mechanical noise, etc. It is widely used in high-grade recording seats, video recorders, electronic instruments and automation office equipment.

Brushless DC motors consist of permanent magnet rotors, multipole winding stators, and position sensors. Position sensing changes the current of the stator windings in a certain order according to the change of the rotor position (that is, the position of the rotor pole relative to the stator winding is detected, and the position sensing signal is generated at the determined position, and is processed by the signal conversion circuit. To control the power switch circuit, according to a certain logic relationship winding current switching). The operating voltage of the stator winding is provided by an electronic switch circuit controlled by the position sensor output.

Position sensors are magnetic, photoelectric and electromagnetic types.

A brushless DC motor using a magnetically sensitive position sensor has a magnetic sensor element (such as a Hall element, a magneto-sensitive diode, a magnetically-sensitive diode, a magneto-resistor, or an application-specific integrated circuit) mounted on a stator assembly. To detect changes in the magnetic field generated by permanent magnets and rotors.

A brushless DC motor adopting a photoelectric position sensor has a photoelectric sensor arranged on a stator assembly at a certain position. A shading plate is mounted on the rotor, and the light source is a light emitting diode or a small light bulb. When the rotor rotates, due to the action of the shading plate, the photosensitive components on the stator will generate pulse signals intermittently at a certain frequency.

Brushless DC motors with electromagnetic position sensors are equipped with electromagnetic sensor components (such as coupling transformers, proximity switches, LC resonant circuits, etc.) on the stator assembly. When the position of the permanent magnet rotor changes, the electromagnetic effect will make the electromagnetic sensor. Generates a high frequency modulated signal (its amplitude varies with rotor position).

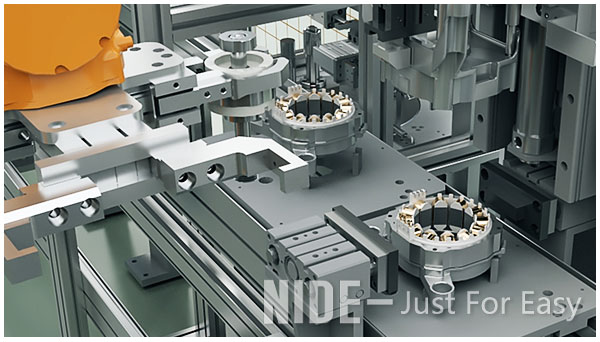

NIDE fully automatic motor assemble line is suitable for varies type induction motor assembly, BLDC motor assembly, universal electric motor and DC motor assembly, It could automatically assemble the rotor, armature, stator and motor components together . It is used for washing machine motor, fan motor, BLDC motor, DD motor, electric bicycles motor , electric vehicle motor , hub motor, DD BLDC washing machine motor , compressor motor, vacuum cleaner motor, power tool motor, wiper motor, mixer motor, RO pump motor, NEMA motor, DC motor, etc. It features fast, efficient, accurate, easy set-up, user-friendly programming and tooling flexibility.